Projects

We put together automated solutions to optimize daily processes

Packing cell

ButtonMPAC

The task was to create a machine that could assemble 3 parts as well as a control unit that sorted out any defective items before packaging.

The request was for a compact machine that could be flexible. The result was a machine with 5 interchangeable dedicated assembly stations, with a capacity of 60 parts per minute.

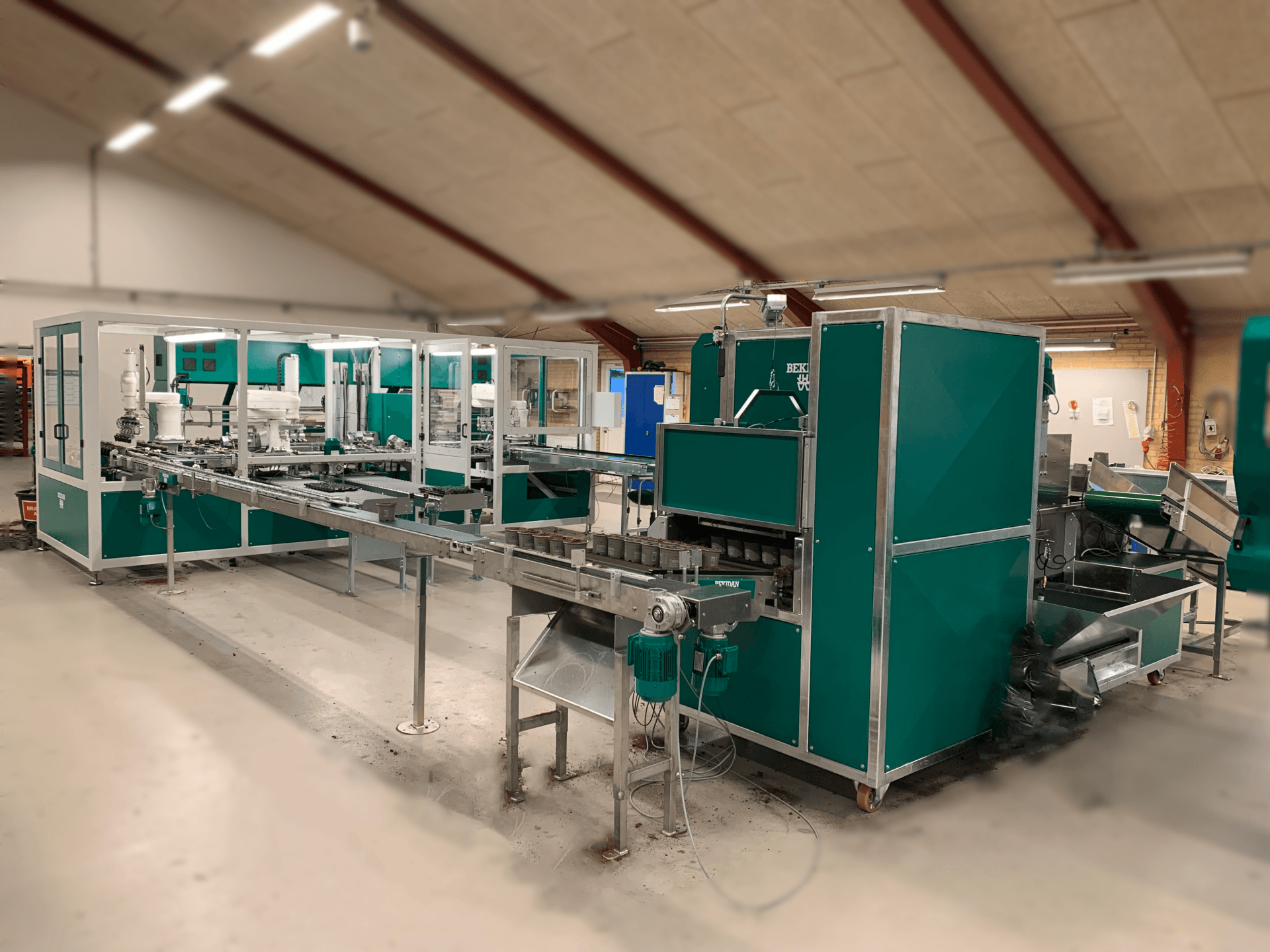

Potting machines

Button1000 trays per hour

The starting point here was a standard BEKIDAN Potting Machine, but since the request was for a larger capacity than what just one machine could deliver, a solution was created by connecting two machines.

A conveyor belt distributes soil to both machines. Both Potting Machines send trays out on a belt, giving customers a capacity of 1000 trays per hour.

In this way, a uniform flow was created with the possibility of producing up to 54,000 pots per hour.

Plant stresses

ButtonPlant stressing

The task was a solution that could strengthen the plants so that they had better rooting, increased stability and stronger growth.

The solution was an artificial "wind" that, by sweeping over the plants, stresses them to create better stability and increased growth.

The plant stressors are controlled by a clock that starts them at the requested interval.

Stick line

ButtonSorting & planting in pots

The request was for a machine that could sort and plant small plants in pots.

The result was camera sorting of the plants, two return conveyer belts and a Plant Robot.

In front of this set-up you see a Bekidan Potting Machine with drilling unit, ready with pots for the plants, that are ready to be planted.

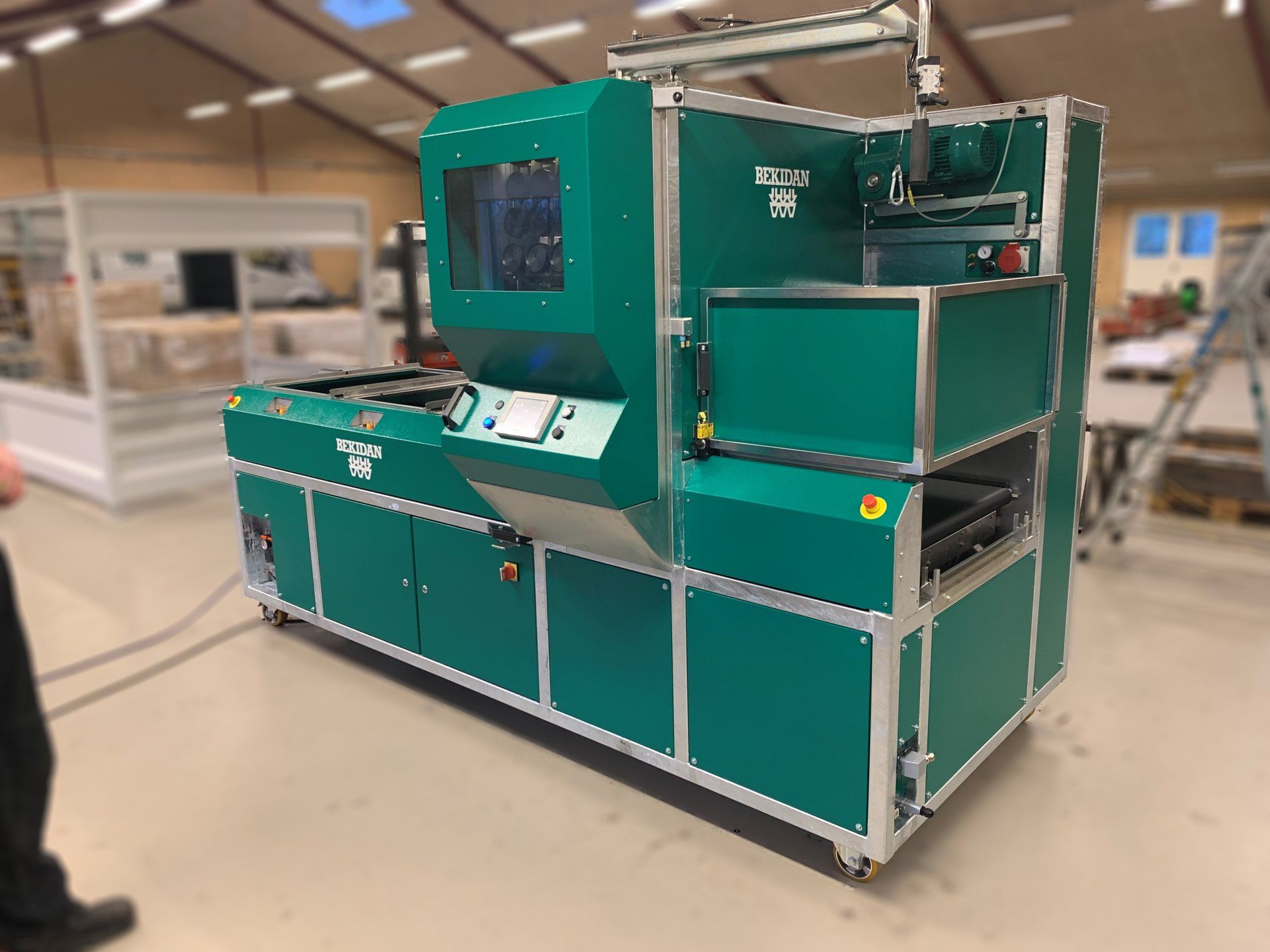

Packing machine

The task here was a machine that could pack a precise number of items into a box with great care.

The customer has a specification for how little the items should be affected by the process, as well as a speed target that must be met.

Last but not least, there was a great wish for a compact unit, ready to be built together with an existing machine.

Sorting plant

ButtonPlant sorting

The task was a machine that could pick up plants directly from the mobile bench and sort them.

The result was a set-up with two robots which pick up plants directly from the mobile bench, coming from the greenhouse. The robots get coordinates from a 3D camera and place the plants in pallets/cups.

A camera then sorts the plants so that those ready for sale can be packed immediately and those that are too small are placed back on the mobile bench and returned to the greenhouse.

Your challenge

Your project?

We hope that our site has been able to inspire with both some of the solutions we have created, but also the prospect of the projects we will be doing.

So don't hesitate to get in touch and tell us about your project.